Heat exchangers, tube bundles and steam generators for your individual heat transfer tasks and problems

Our company has been active since 1955 in thermal engineering (e.g. tube bundles, heat exchangers and steam generators). Between 1955 and 1981 we named as the firm Gustav Schäfer Abteilung Apparatebau. After the successful conversion into a limited liability company the company name is GSD Wärmetechnik GmbH.

We are your competent partner for many of your heat transmission problems. For every problem we give you the solution. According to your application the heat exchanger can be use for counterflow heat, for condensation and for steam generation. Our motto is:

Particular challanges ask for individual solution - both in terms of design and with respect to the consideration of physical and geometrical conditions. At GSD Wärmetechnik we always keep an eye on the issues of our clients and try to find the best solution in the field of steam generation, shell and tube exchangers and steam technology.

Engineering of heat exchangers

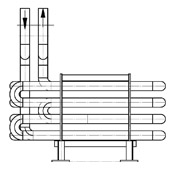

All our products are designed and constructed by our engineers. Therefore you are sure, that we optimize your heat exchanger for your problem. To find the best solution, we show you some different constructions of heat exchangers. For example:

- U-tube heat exchanger

- Straight tube heat exchanger (horizontal / vertical)

- Stainless steel heat exchanger for special cases (floating head exhanger)

- Steam generator or steam converter for technical requirements

- Steam generator or steam converter for sterilisation

- Safety heat exchanger

- Heat exchanger for special cases

- Tube bundles for installation in vessels

- Straight tube bundle

- Tube bundle for replacement

GSD Wärmetechnik is a manufacturer of heat exchangers in different designs for the most versatile usages such as the condensation of steams or gas-steam mixtures, the heating of fluids with fluids, steam or thermal oil, the cooling of fluids with water, condensate, oils, operating fluid of diverse composition with fluids like water or brain.

Furthermore we produce steam generators that are heated with hot water, steam or thermal oil. These steam generators are used for example in air conditioning systems, for sterilisation or for the conversion of steam of high pressure to a lower system pressure.

Another of our products are tube bundles that can be installed in vessel of diverse designs.

Our heat exchangers have either interchangeable or not interchangeable tube bundles. The condensation or the evaporation take place either in the tube bundle or shell. According to your application of the heat exchanger, you can warm up or cool down liquids or gasses.

The media are managed as far as possible in the counterflow principle. The name counterflow heat results from these perfusion.

Important for the construction or for the materials is the corrosion behaviour of the heat transfer medium.